Meeting regulatory Requirements in the diverse world of medical devices requires deft job management. This may be a difficult and complex job. You need to balance the requirements of a good deal of different parties whilst remaining within budget and holding to tight deadlines. The clinical requirements and security of the apparatus are paramount and must be shown. Partnering with Medical Engineering Technologies will make sure that this portion of your job runs efficiently and easily. Our technicians are often devising sophisticated protocols under stress, and they are fully resourced to ensure rapid delivery of test function. We can’t guarantee exactly what the outcomes will be or shorten the dwell time in a test, but we can guarantee accuracy and efficiency.

Partner with MET to your Medical device testing and we guarantee:

- Rapid and competitive quotes

- Rapid project commencement

- Rapid access to gear

- Efficient Shipping and reporting

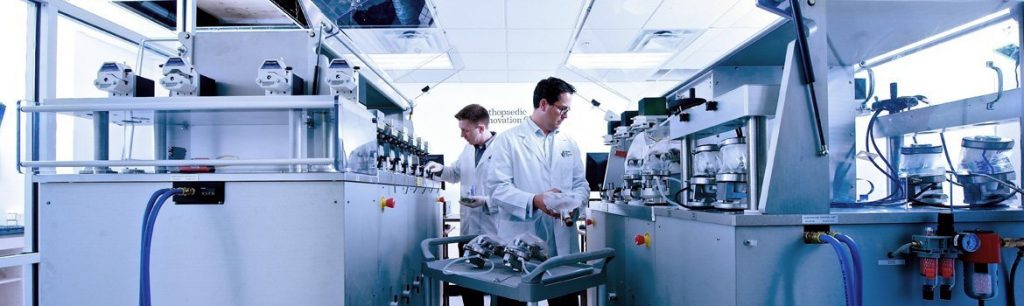

We work to ISO 17025 and GMP. After a contract is in place purchase order, statement of work or technical arrangement we will respond with a protocol to your acceptance or comment within days.Right medical device testing is the procedure for demonstrating that the device will reliably and safely function in use. In new product development, extensive Design Validation Testing is implemented. Including performance testing, toxicity and chemical analysis, and sometimes human factors as well as clinical testing. Ongoing quality assurance testing is generally more restricted. This will usually consist of dimensional tests, some practical tests, and packing verification.MET is supporting medical Device companies throughout the world, having ran thousands of projects. Our key engineers have been involved in developing medical devices for blue chip anaesthetics makers.